Description

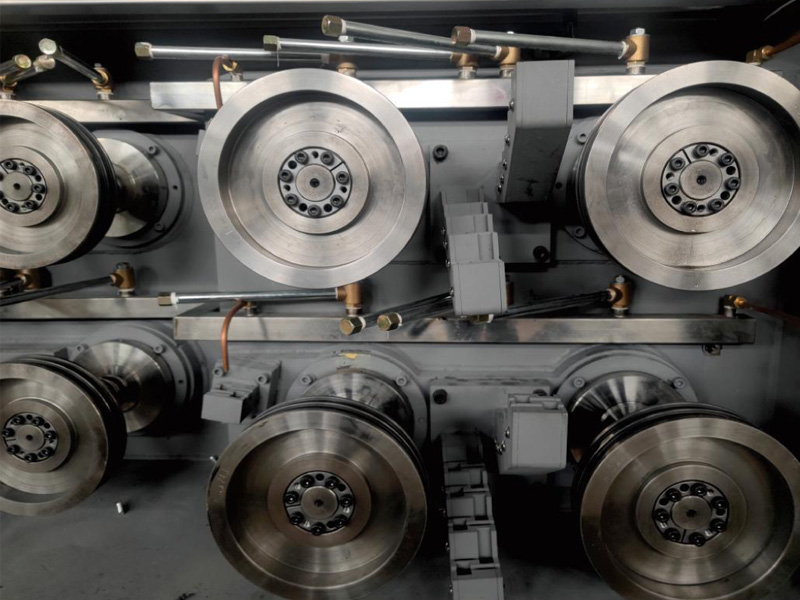

1、Driven by high precise helical timming belt; quick die change can be achieveddual motors drive.

2、The capstan and die lubrication system is in emulsion spraying with force from inside of die holders design; In this way,the lubrication is more sufficient and it save space, moreover, it makes operation more convenient.

3、Annealing contact copper rings, nickel tubes are made from special alloy; it can ensurea longer service life.

4、The annealer control system is in zero length preset voltage design, so that it can ensure stable annealing of wires in the process of machine start and stop.

|

Machine type

|

MD220-21

|

MD180-25/4

|

|

No. of wire

|

4

|

4

|

|

Inlet dia (mm)

|

∅1.2-∅2.05

|

∅0.5-∅1.2

|

|

Outlet dia (mm)

|

∅0.15-∅0.6

|

∅0.08-∅0.3

|

|

Drawing speed (max)(m/min)

|

1800

|

1800

|

|

No. of dies

|

21

|

25

|

|

Drawing ring dia (mm)

|

∅220

|

∅180

|

|

Transmission type

|

Timing biet/Falt belt

|

|

|

Online continuous annealer

|

||

|

Annealer speed (m/min)

|

1800

|

2000

|

|

Annealer wheel dia (mm)

|

∅200

|

∅120

|

|

Max annealing voltage(V)

|

DC60

|

DC60

|

|

Max annealing current(A)

|

1000

|

300

|

|

Take up type(optional)

|

||

|

630 Single Reel Take-up Machine

|

✓

|

✓

|

|

800 single reel take-up machine

|

✓

|

✓

|

|

280 single reel take-up machine

|

✓

|

✓

|

Reviews

There are no reviews yet.