Description

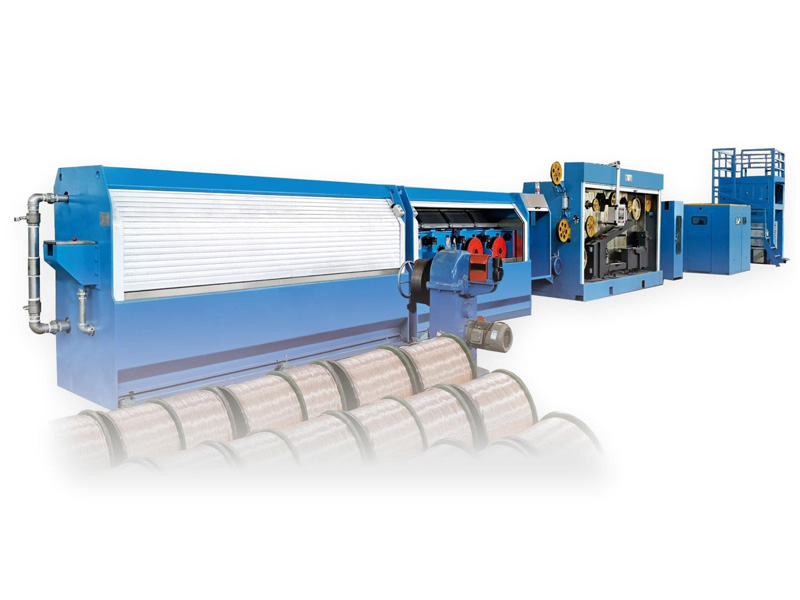

1、Horizontal serial structure. Dual motor drive.Quick die change can be achieved.

2、High-precision grinding helical gear transmission.High efficiency,low noise.

3、Drawing capstan combined design.

4、Fully immersed lubrication cooling to ensure the quality of the wire.

5、DC/AC annealing control,annealing automatic tracking speed.

6、Ensure that the elongation of copper wire is stable and uniform.

|

Machine type

|

DR400-7

|

DR450-9

|

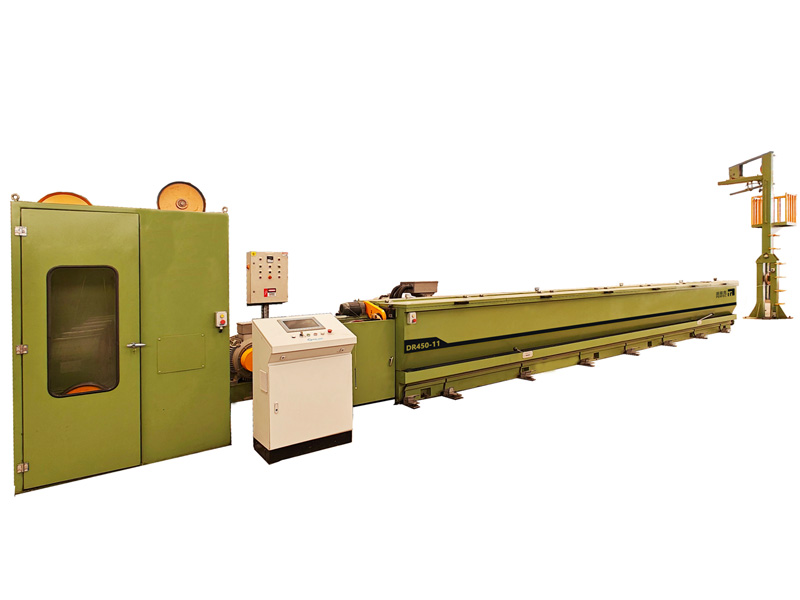

DR450-11

|

DR450-13

|

DR450-15

|

|

Inlet dia (mm)

|

∅8

|

∅8

|

∅8

|

∅8

|

∅8

|

|

Outlet dia (mm)

|

∅2.6-∅3.5

|

∅2.0-∅3.5

|

∅1.6-∅3.5

|

∅1.2-∅3.5

|

∅1.0-∅3.5

|

|

Drawing speed (max)(m/min)

|

800

|

1200

|

1200

|

1500

|

1800

|

|

No.of dies

|

7

|

9

|

11

|

13

|

15

|

|

Die OD (max)(mm)

|

∅55

|

∅55

|

∅55

|

∅55

|

∅55

|

|

Capstan dia (mm)

|

400

|

450

|

450

|

450

|

450

|

|

Finished capstan dia (mm)

|

400

|

450

|

450

|

450

|

450

|

|

Main motor power(kw)

|

AC160

|

AC200

|

AC250

|

AC280

|

AC280

|

|

Finshed capstan motor power(kw)

|

AC55

|

AC75

|

|||

|

Lubrication type

|

Lmmersed Type

|

||||

|

Gear、bearing lubrication

|

Pump forced oil

|

||||

|

Overall dimensions(m)

|

4.36*2.7*1.2

|

5.36*2.7*1.2

|

7.9*1.8*1.2

|

9*1.8*1.2

|

10.2*1.8*1.2

|

|

Online continuous annealer

|

|||||

|

Annealer speed (m/min)

|

700

|

900

|

1200

|

1500

|

1800

|

|

Annealer wheel dia (mm)

|

∅450

|

∅450

|

∅450

|

∅450

|

∅450

|

|

Max annea ing voltage(V)

|

AC55V Or DC60V

|

||||

|

Max annealing current(A)

|

5000

|

5000

|

5000

|

5000

|

5000

|

|

Take up type (optional)

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Single Spooler

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Double Spooler

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Fully automatic double Spooler

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Down Co1ler

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

Compact spooler

|

✓

|

✓

|

✓

|

✓

|

✓

|

Reviews

There are no reviews yet.