Description

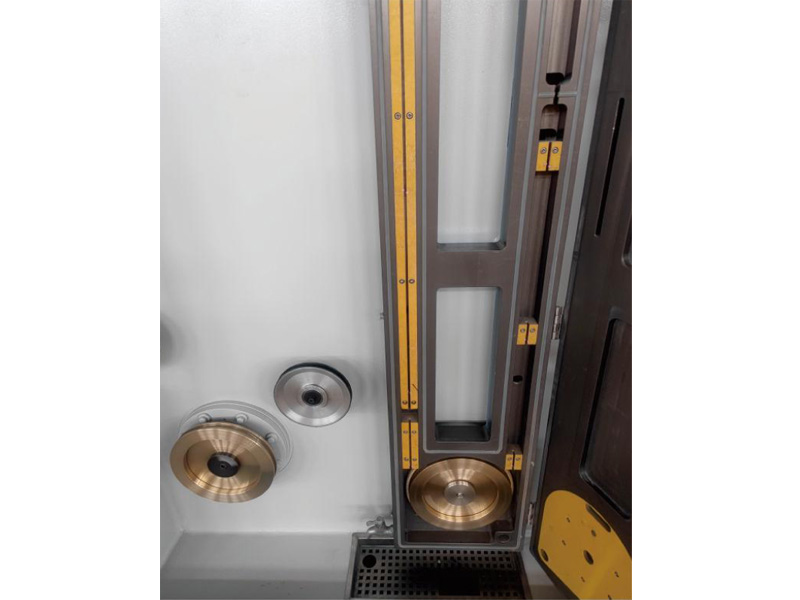

1、High-precision grinding helical gear Iransmission,forced oil lubrication control,low noise.

2、Full immersion lubrication design.

3、DC annealing control, annealing automatic tracking speed.Ensure that the elongation of copper Wire is stable and uniform.

4、The take-up tension PID is automatically adjusted to ensure that the tension during the wire drawing process is always stable.

5、Smaller compression ratio design is more suitable forthe production of large-size conductors,such as the production of wire and single conductor.

|

Machine type

|

DR300-9

|

DR280-13

|

DR250-17

|

DR250-21

|

|

Inlet dia (mm)

|

∅2.6-∅3.5

|

∅2.6-∅3.5

|

∅2.6-∅3.5

|

∅2.6-∅3.5

|

|

Outlet dia (mm)

|

∅1.0-∅2.76

|

∅0.7-∅2.0

|

∅0.4-∅1.6

|

∅0.3-∅1.2

|

|

Drawing speed (max)(m/min)

|

1200

|

1500

|

1800

|

1800

|

|

No.of dies

|

9

|

13

|

17

|

21

|

|

Slip ratio of m/c (%)

|

20%+16.67%

|

17%+13%

|

20%+15.5%

|

15.5%+13%

|

|

Capstan

|

Tungsten carbide

|

|||

|

Capstan dia (mm)

|

300

|

280

|

250

|

250

|

|

Finished capstan dia (mm)

|

300

|

280

|

250

|

250

|

|

Bobbin size(mm)

|

0500~0630(Optional)

|

|||

|

Bobbin loading&unloading type

|

Bi-shafts cone

|

|||

|

Main motor power(kw)

|

AC45

|

AC55

|

AC55

|

AC55

|

|

Spooler motor(kw)

|

AC15

|

AC15

|

AC15

|

AC15

|

|

Revise system

|

Automatic take-up control

|

|||

|

Displacement Detection device

|

Pneumatic by swing arm

|

|||

|

Gear、bearing lubrication

|

Pump forced oil

|

|||

|

Online continuous annealer

|

||||

|

Annealer speed (m/min)

|

1200

|

1500

|

1800

|

1800

|

|

Annealer wheel dia (mm)

|

∅250

|

∅250

|

∅250

|

∅250

|

|

Max annealing voltage(V)

|

DC60

|

DC60

|

DC60

|

DC60

|

|

Max annealing current(A)

|

2000

|

2000

|

1500

|

1200

|

|

Take up type (optional)

|

||||

|

Single Spooler

|

✓

|

✓

|

✓

|

✓

|

|

Double Spooler

|

✓

|

✓

|

✓

|

✓

|

|

Fully automatic double Spooler

|

✓

|

✓

|

✓

|

✓

|

|

Down Coiler

|

✓

|

✓

|

✓

|

✓

|

Reviews

There are no reviews yet.