Description

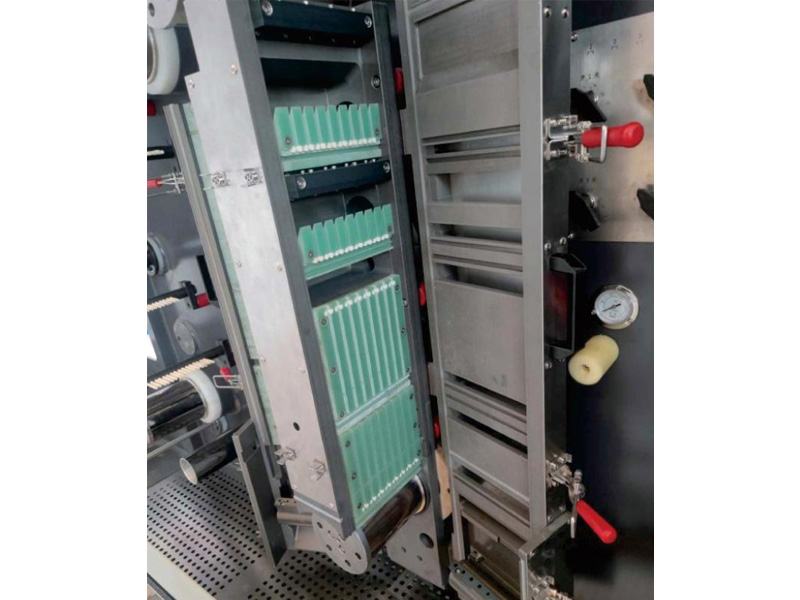

1、Driven by high precise helical gears; particular oil lubrication mechanism;quick die change can be.

2、The capstan and die lubrication system is in emulsion spraying with force from inside of die holders design;In this way,the lubrication is more sufficient and it save space, moreover, it makes operation more convenient.

3、Annealing contact copper rings, nickel tubes are made from special alloy; it can ensure a longer service.life.

4、The annealer control system is in zero length preset voltage design, so that it can ensure stable annealing of wires in the process of machine start and stop

|

Machine type

|

MD120-22/16

|

MD100-27/24

|

MD100-27/16

|

MD100-22/16

|

DR450-15

|

|

No. of wire

|

14/16

|

24

|

16

|

16

|

16

|

|

Inlet dia (mm)

|

∅2.6

|

∅2.6

|

∅2.6

|

∅1.6-∅2.0

|

∅1.5-∅1.8

|

|

Outlet dia (mm)

|

14/16*0.25-0.8

8*0.5-1.35 |

∅0.15-∅0.4

|

∅0.15-∅0.4

|

∅0.15-∅0.4

|

∅0.10-∅0.4

|

|

Drawing speed (max)(m/min)

|

1800

|

1800

|

1800

|

1800

|

1500

|

|

No. of dies

|

19/22

|

27

|

27

|

22

|

25

|

|

Drawing ring dia (mm)

|

∅120

|

∅120/∅100

|

∅120/∅100

|

∅100

|

∅100

|

|

Transmission type

|

Gear

|

||||

|

Online continuous anneale

|

|||||

|

Annealer speed (m/min)

|

1500

|

1800

|

1800

|

1500

|

1500

|

|

Annealer wheel dia (mm)

|

200

|

∅140

|

∅140

|

∅140

|

∅140

|

|

Max annealing voltage(V)

|

DC60

|

DC60

|

DC60

|

DC60

|

DC60

|

|

Max annealing currnt(A)

|

5000

|

5000

|

3000

|

3000

|

2500

|

|

Take Up Type(optional)

|

|||||

|

630 single disc winding machine

|

✓

|

✓

|

✓

|

✓

|

✓

|

|

800 single disc winding machine

|

✓

|

✓

|

✓

|

✓

|

✓

|

Reviews

There are no reviews yet.